Robline | SKU:

Robline Dinghy Star Pro

Sale price

$1.93

Regular price

$2.07

Unit price

Unavailable

Availability: Price Per Foot

Shipping and Delivery

Free shipping for orders of $98 or more (US Continental)

- Free shipping for orders of $750 or more (International)

- Add 3 business days to the standard shipping time for USPS deliveries.

- UPS and FedEx Ground usually take 2 to 5 business days for in-stock orders.

- UPS and FedEx deliver on Saturdays only for Friday overnight shipments, which may incur an extra

charge. - Orders that apply for free shipping will be delivered between 8 and 10 business days.

- International customers will be responsible for any applicable import duties,fees, or taxes.

- Oversized items like whisker poles, spinnaker poles, and tracks over 7 feet require freight shipping, with an estimated cost of $500 depending on the destination.These orders must be delivered to a

commercial address, such as a marina, yacht club, or boatyard where your sailboat is located.

A recipient must be present to sign for the delivery upon arrival,For more info, Click Here.

Robline Dinghy Star Pro 3mm - 1/8" (DST-3).

Standard rope used as halyard on 49er & Co. Dinghy Star Pro is the standard rope for skiff and dinghy classes. It excels due to highest abrasion resistance at minimum stretch.

• Core: Dyneema® SK78.

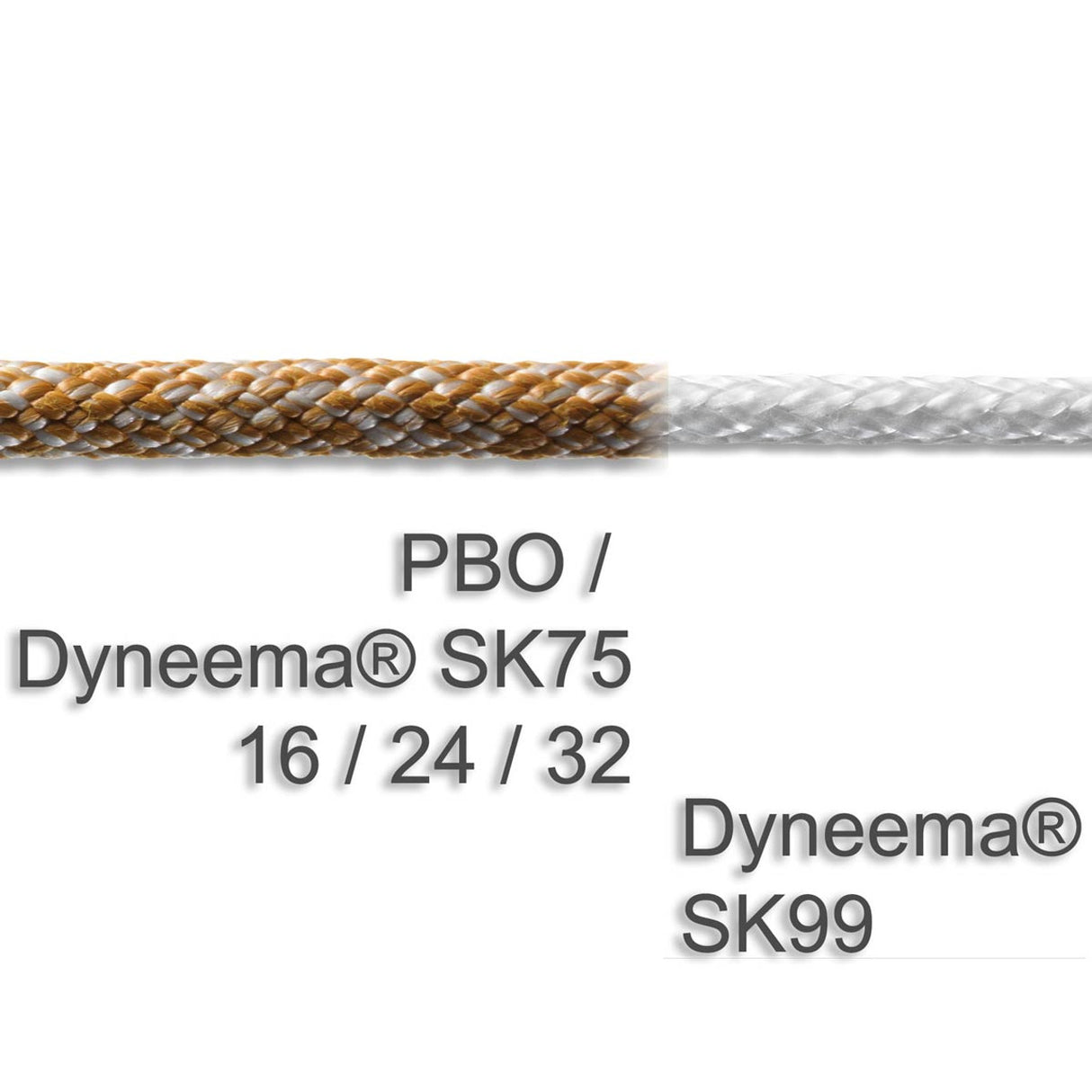

• Cover: PBO/Dyneema® SK78 / Technora®/XLF / 16/24/32.

• Field of use: Crossover: This line is suited for use as both a halyard and a sheet.

• Core: Dyneema® SK78.

• Cover: PBO/Dyneema® SK78 / Technora®/XLF / 16/24/32.

• Field of use: Crossover: This line is suited for use as both a halyard and a sheet.

Technical Description *

| Size Diameter | Weight Per 100 ft | Weight Per g/m |

Min. Breaking Load** | ||

|---|---|---|---|---|---|

| Imperial | Metric | Imperial | Metric | ||

| 1/8 in | 3 mm | 0.007 lb | 6 g | 899 lb | 400 daN |

| 5/32 in | 4 mm | 0.012 lb | 11 g | 1798 lb | 800 daN |

| 3/16 in | 5 mm | 0.018 lb | 16 g | 2922 lb | 1300 daN |

| 1/4 in | 6 mm | 0.025 lb | 23 g | 4271 lb | 1900 daN |

* The data are typical values without warranty or guarantee.

** The value in daN (1 daN is about 1 kg) indicates the load at which the rope would break. The specified breaking loads are values determined in testing in our laboratory. In practical use, these values may deviate depending on the type of use. The breaking loads were determined for free lengths of rope and will be decreased by splices or knots. When defining a rope's dimensions, we recommend to apply a ratio of working load to breaking load of at least 1:5!

Robline's top-of-the-line dinghy rope - developed and produced without compromises

This product was developed without compromises, contains only the very best raw materials, and lives up to the latest manufacturing standards. Robline's aim was to take Robline's dinghy ropes to another level, something we have definitely accomplished in the form of Dinghy Star Pro. By using Dyneema® SK99 fibers in the core, we obtained extremely high breaking strength values in the core, combined with zero creep - simply perfect!

Its cover made out of PBO/Dyneema® SK78 makes Dinghy Star Pro extremely resistant to abrasion and UV. The grippiness of the PBO used for the cover makes this rope grippier, further improving its functionality, especially when it is used as spi halyard. Dinghy Star Pro is a must-have for every regatta racer.

Aplications: Dinghy

• Spinnaker/ Gennaker Halyard (1).

• Foresail Halyard (2).

• Tack-Line (3).

Features

• Lowest stretch and highest breaking strength.

• Abrasion resistant.

• Low weight.

• Soft.

• Kink free.

• Resistance to high temperatures.

• Good ability on winches.

• Good in cleats.

• Low water absorption.

• Spliceable.

• Dyneema® core: lowest weight with the highest breaking strength.

Polyethylene which is the raw material for Dyneema® is changed on a molecular basis and in addition is stretched in one direction. These stretched molecule chains increase the breaking strength and decrease the elongation. Therefore Dyneema® has the lowest stretch at break of all synthetic fibers. Dyneema® has a very low specific weight and is therefore buoyant. The only disadvantage is that it creeps more than some other raw materials.

This means the cover can easily be removed from the rope ends without reducing the breaking strength due it's fiber shows a permanent elongation under load. Dyneema® is used as core material in high-tech ropes. The core will carry the load whereas the cover is just used for abrasion and light protection. Therefore Dyneema® it has too a good abrasion resistance and resistance against sunlight.

| Raw Material | UHMWPE |

| Strength (daN/mm2) | 345 |

| Specific Weight (g/cm3) | 0.97 |

| Water Intake % | 0 |

| Sun Resistance | very good |

| Elongation | 3.5 |

| Abrasion Resistance | very good |

| Creep | at high loads |

| Melting Temperature | 140° |

• PBO.

Very high breaking strength as well as very low elongation and creep values are 12-strand PBO braid features. This high-tech product is used in all cases involving extremely high loads.